Custom Steel Fabrication

Manufacturing Services

• Shearing – up to 3/8” x 24’

• Bending – press brakes to 1000T x 24’

• Punching – round, square, slot, and hex

• Welding – MIG, TIG, and stick welders

• Phosphatizing – high pressure acid

• Sandblasting – structural scale removal

Technical Services

• Product Design Assistance

• Computer Aided Drafting (CAD)

• Computer Aided Engineering (CAE)

• Detailing for Shop Fabrication

• Painting – electrostatic and airless

• Equipment Assembly

Tooling: Our shop is well equipped for shearing and air bending steel sections up to 24’ long, with mild steel shear capability up to 3/8” thick, and press brake capacity up to 1,000 tons. Overhead hoists are provided for rapid movement of large cumbersome sheets, with vacuum lifts and other attachments to handle your product with minimal damage. Available press brake tooling includes right angle and hem dies, gooseneck punches, and flattening dies, as well as multiple Strippett punches and a variety of other special purpose tooling.

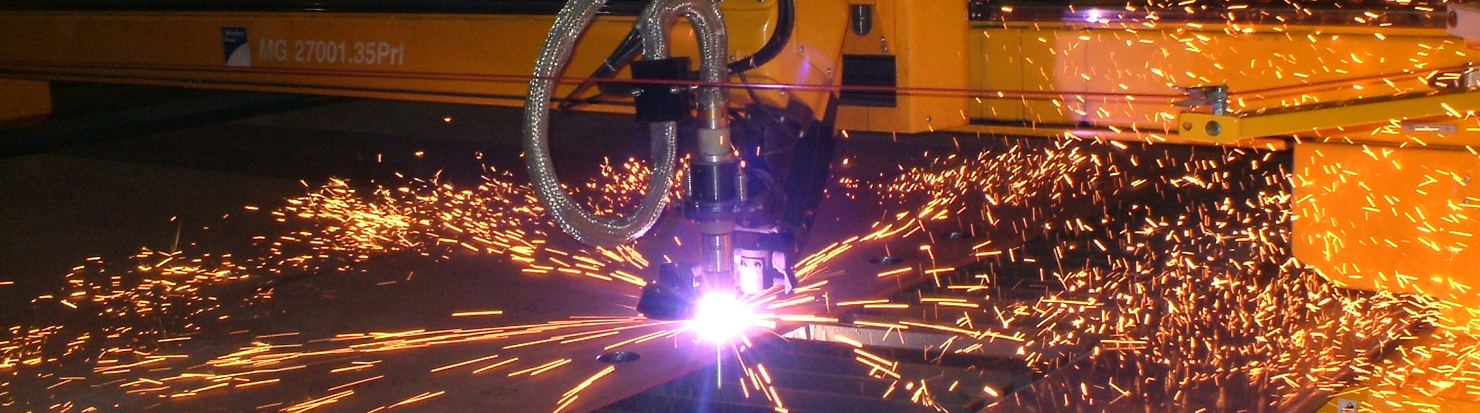

Fabrication: Many parts require other operations in addition to shearing and forming. Punching and cut-off requirements are typically met using our Mubea ironworker. Structural shapes can also be cut on one of our band saws, with capacity for I-beams up to 14” deep. Beam punches and magnetic drills are used on structural iron, with handheld plasma cutters and other tooling for other operations. Our machine shop also includes multiple vertical mills, pipe threading equipment, drill press, metal lathe, and other steel fabricating machines.

Welding: The welding department includes extensive wire welding equipment for MIG welding of mild steel, and we have recently added capability for TIG welding stainless steel and aluminum. Our staff is also experienced in assembly of material handling machinery and similar equipment.

Finishing: Metal preparation prior to paint application is critical. Structural iron is sandblasted prior to welding for scale removal, and all sheet steel components are acid phosphatized prior to painting to remove oil residue and etch the steel for better paint adhesion. Standard paint coatings are applied using our electrostatic paint equipment, with additional equipment for application of special zinc based epoxy primers and weather resistant urethane coatings.